We are in our third week at the Boat Works. Just when we thought we were going swimmingly well, our shipwright investigated the area of delamination and found a surprise for us: some rot to cut out!

143 Boat Building coming to the rescue

Ryan Thacker who runs 143 Boat Building has been our shipwright for six years. He has been fantastic and we rely on him for Anui’s maintenance. We recommend him to other cruisers without hesitation. We were concerned about an area of possible delamination near the port engine hatch and had brownish water drips coming inside the hatch under a stand up pulley block, which Wade removed. We asked Ryan to have a look.

The pulley screws were soaking wet with wood pulp. That’s never a good sign! Tap, tap, tap along the outside edge of the hatch. There was a recognisable dull sound around and down from where the pulley was. Ryan started digging and found a section of the beam the pulley was affixed to was totally rotten. Although the boat construction is foam and fibreglass, hardwood is used where gear such as pulleys, cleats, winches and stanchions are affixed to the deck.

This particular stand up pulley on each side of the boat is the one withstanding the greatest load when we sail under screecher or spinnaker. We are talking tons of pressure so it is a wonder it did not rip off the deck under sail! As we always do when we find something nasty, we bite the bullet and get it fixed properly.

Once you find rot, you only have one option: dig it all out. Rot is a fungus, and like a cancer, you have to get it all and more or it spreads. But you never quite know how far the rotten stuff goes and you feel sick in the stomach as the multi tool cuts, and cuts, and cuts and what comes out is mush and more mush.

Ryan and his team, Brian and Matt, got to work and ended up slicing out a meter long strip along the edge of the hatch, dug out the soggy wood pulp till they got to solid timber. We had visions of the whole edge of the boat being affected and did not get much sleep that night, but luckily there was only a thin 80cm section to deal with, so they cut out a meter length for good measure.

The process of reconstruction started the next day. Each step takes an hour or two, then it is a matter of letting things dry before you move on to the next step. The team worked at it over several days, including the weekend. Once the area was all cleaned up, they butted in and epoxied new pieces of timber. Next came the grinding, bogging, sanding, fibre-glassing, filling, grinding, filling again, fairing, priming, painting, more painting and finally the re-installation of the stanchion, pulley and engine hatch. Here is a slideshow showing the long process. It took a bit over a week.

The rest of the maintenance

Most other items on the work list were ticked off, bar two:

- Marine Mechanical Solutions completed the Yanmar engines service

- Chris at Shine Stainless Steel repaired and strengthened the davits and welded the dinghy hole in the aluminium hull we had temporarily patched back at Hinchinbrook

- Engineer Les Fitzpatrick refurbished our back up autopilot

- The antifoul and Propspeed were applied by 143 Boat Building

- We completed all our own tasks early in the week, a good excuse to catch up with other cruisers, our cousins Grant and Deb, our friend Bill who lent us his posh car for two weeks, even Wendy, graphic designer for Australian Multihull World!

Apart from the repair to the port side, two tasks were holding us up:

We had a long wait for the chain and anchor to be re-galvanized by PDM Galvanizing and Transport. It took 17 days to get done… okay if you are stuck in the yard for a while as we were, but too slow if you are in a hurry! We got that marked and back on board.

We also had ordered new seals for the escape hatches and for the small hatches at the base of the mast, all of which were leaking! The first ones to arrive were the ones for the small hatches.

The seals for the escape hatches took longer. They were ordered in plenty of time, but the wrong ones got delivered. The correct ones have finally turned up and are being fitted as we post this… one less thing to worry about!

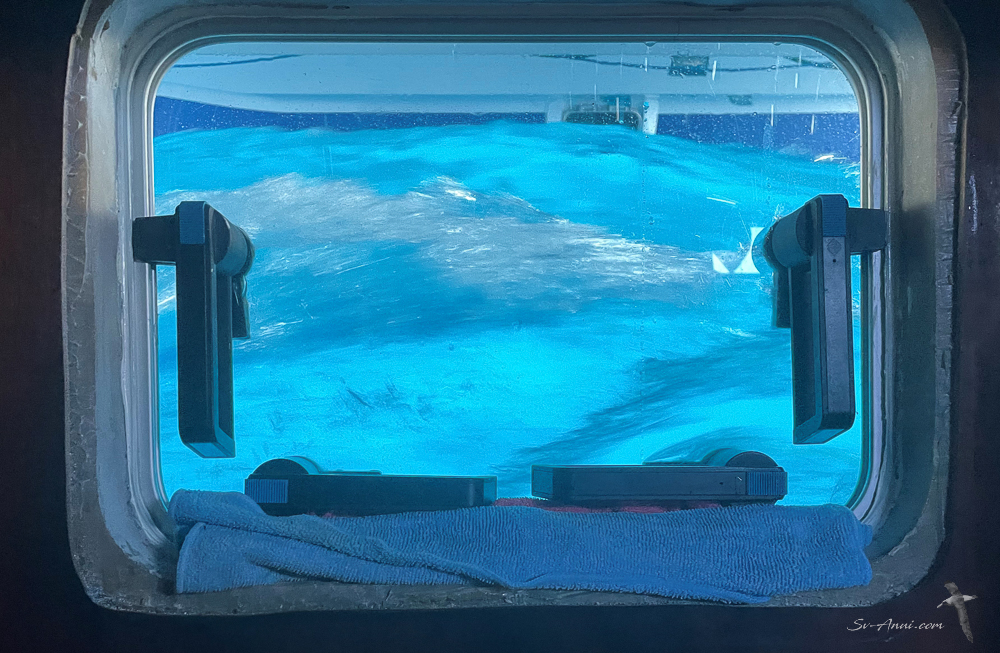

Our splash back was supposed to happen on Wednesday morning but we were obviously not ready to go. We are now wait-listed to go back in the water on Monday the 18th December. There is a number of other boats also waiting. Fingers crossed we can get in! This last week has been particularly hot. The boat is baking on the concrete and life is not very pleasant for us. Our pussycat Bengie has been suffering in the extreme heat too. We keep finding her flaked out wherever she can find a comfy spot.

We can’t wait to get out of captivity and back in the water!

Well one good thing the weather has been on your side Have a lovely Christmas Cheers Dianne

>

Hi Dianne, true, at least no rain this week! Enjoy Christmas.

Wow, I am glad that the rotten glass was discovered and repaired! That could have been a disaster when underway. You guys are stuck in dry dock a long time now, bummer. Cross your fingers your splash back is coming soon!

Looks like we’ll have been on the dry for three weeks. Even without the wood rot, we’d have had to wait because of the seals to the escape hatches anyway… Getting there…

Those hatch seals are super important! Well worth the wait!

Yes, can’t go in the water without… quick way to sink!

Christmas has come early for Anui with so many new sparkly bits and pieces. Nearly your turn. Hoping you hit the water and get going on your journey south again asap.

Hope so too, Ann! Anui looks a treat… we look a bit raggedy!

We feel for you. You will be so glad to get back in the water. I bet Bengie can’t wait to feel the wind in her hair…she looks exhausted…

Hi Trish, yes we are all feeling a bit ordinary but definitely seeing the splash back getting closer.

Yes well – it is easy to say ‘it is as it is’ . . . but the presence of a situation not in one’s control can be frustrating! It seems to have been three steps forward, one back! Am just glad the rot was discovered where it could immediately be repaired! Hate to think what that did to the bank balance !!! Will be glad to see you on a southerly path at last and am wondering where the days of Yule may be celebrated . . . best for that!!!

Hi Eha, best not to study the bank balance too much… way too depressing! We know what we worked hard for all our life: to be able to pay for Anui – also known as Costalot.

Hopefully our next post will bear good news of our splash back and escape. Christmas somewhere in the deep blue sea… the Solitaries have a nice ring to them. With no kids and no parents… Christmas is just another day for us but we will celebrate quietly being lucky to live this life.

Well, I am a landlubber but your last para is totally true of me also. Shall send hugest, warmest good wishes a week down the line . . . oh, tummyrubs meanwhile please . . .

Tummy rubs gratefully accepted by all 😉😽

Oops – sincere apologies but, due to time limitations tummy rubs only offered to four legged favourites!

😦

Great find there Wade. Could have been disastrous if the block pulled out underway. You always seem to have a few little unexpected surprises at haulout . All the best for a Monday splash

Thanks Graham… always the chance to investigate when we are on the hard. Better to do find these things out and fix them before they create havoc. Monday splash confirmed!

That rot was a good find. Can’t begin to imagine the pulley ripping out under sail! Enjoy your Christmas guys 😁

Hi Elgar, yes we would have been in serious strife. We complain about the repairs, but we have both learned over the years to question and investigate anything that does not look right. It keeps us safe…

Very wise, nothing worse for you than serious breakages out in the blue …